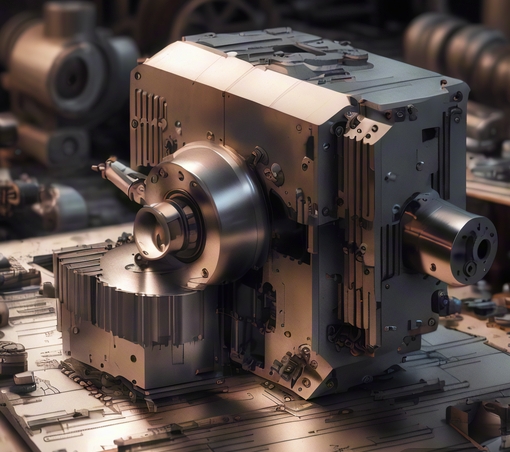

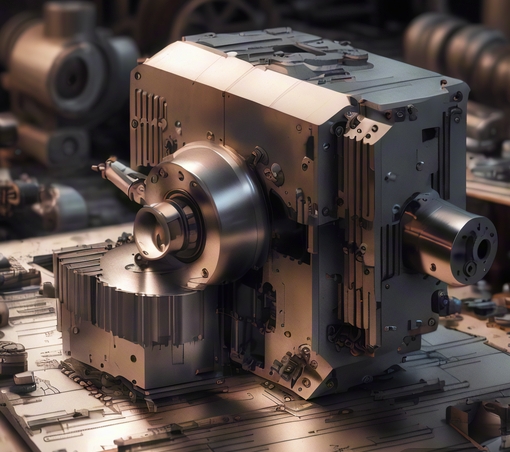

In the world of precision engineering and manufacturing, CNC milling has revolutionized the way we shape and mold materials. When it comes to working with aluminum, a material known for its versatility and strength, HeroCnc stands out as a leading brand that delivers exceptional CNC milling solutions. In this comprehensive guide, we will explore the ins and outs of CNC milling aluminum with HeroCnc, showcasing the brand’s commitment to precision, innovation, and efficiency.

Understanding CNC Milling Aluminum:

CNC milling is a subtractive manufacturing process that involves removing material from a workpiece using computer numerical control (CNC) machines. When it comes to aluminum, CNC milling offers unparalleled precision, making it a preferred choice for industries ranging from aerospace to automotive and beyond. HeroCnc takes this process to new heights with cutting-edge technology and a commitment to quality.

HeroCnc’s CNC Milling Aluminum Capabilities:

- Precision Machining:HeroCnc’s CNC milling machines are equipped with advanced technology that enables precision machining of aluminum components. From intricate designs to complex shapes, the machines deliver consistent and accurate results, meeting the highest industry standards.

- High-Speed Milling:Time is of the essence in manufacturing, and HeroCnc understands the importance of efficiency. The brand’s CNC milling machines are designed for high-speed operations, ensuring rapid material removal without compromising precision. This is particularly crucial when dealing with large production runs or tight deadlines.

- Versatility in Aluminum Grades:Aluminum comes in various grades, each with its unique properties. HeroCnc’s milling capabilities extend to a wide range of aluminum alloys, including but not limited to 6061, 7075, and 2024. This versatility allows manufacturers to choose the right material for their specific applications.

- Complex Geometries and 3D Machining:The ability to create complex geometries and engage in 3D machining is a hallmark of HeroCnc’s CNC milling solutions. This capability opens up new possibilities for industries that demand intricate and sophisticated aluminum components.

- Surface Finish Excellence:HeroCnc recognizes the significance of surface finish in the final product. The CNC milling machines are equipped to achieve superior surface finishes on aluminum, meeting the aesthetic and functional requirements of diverse applications.

Advantages of CNC Milling Aluminum with HeroCnc:

- Accuracy and Consistency:HeroCnc’s commitment to precision ensures that every milled aluminum component meets tight tolerances and specifications consistently. This level of accuracy is crucial for industries where even the slightest deviation can have significant consequences.

- Cost-Effective Production:While precision is paramount, HeroCnc also prioritizes cost-effectiveness. The efficiency of the CNC milling process, coupled with high-speed capabilities, contributes to cost savings in both time and resources, making it an economically viable solution for manufacturers.

- Reduced Lead Times:HeroCnc’s high-speed milling capabilities translate to reduced lead times for projects. This is particularly beneficial for industries that operate in dynamic and fast-paced environments, where timely delivery is a competitive advantage.

- Quality Assurance:Quality is embedded in HeroCnc’s ethos. The brand incorporates quality assurance measures throughout the CNC milling process, from initial programming to final inspection. This commitment ensures that every aluminum component leaving the facility meets the highest standards.

- Customization Possibilities:The versatility of HeroCnc’s CNC milling machines allows for extensive customization. Whether you need prototypes, small batches, or large-scale production runs, the brand can adapt its milling solutions to suit your specific requirements.

Applications of CNC Milled Aluminum:

- Aerospace Components:The aerospace industry demands precision and reliability, making CNC-milled aluminum components essential for aircraft structures, engine parts, and more.

- Automotive Parts:CNC-milled aluminum is widely used in the automotive sector for components such as cylinder heads, pistons, and transmission parts, where lightweight yet durable materials are crucial.

- Electronics Housings:The electronics industry benefits from the precision of CNC milling for creating intricate housings and components for devices ranging from smartphones to industrial equipment.

- Medical Devices:The medical field relies on CNC-milled aluminum for the production of intricate and customized components used in medical devices and equipment.

- Architectural Elements:CNC-milled aluminum finds its place in architectural design, contributing to the creation of decorative and structural elements in buildings and public spaces.

Tips for Optimal CNC Milling Aluminum Results:

- Choose the Right Aluminum Alloy:Selecting the appropriate aluminum alloy for your specific application is crucial. HeroCnc’s milling capabilities extend to a variety of alloys, each with its unique properties, so consult with experts to make an informed choice.

- Optimize Toolpath Strategies:HeroCnc’s CNC milling machines are equipped with advanced toolpath optimization features. Work closely with the programming team to ensure that toolpaths are optimized for efficiency and precision.

- Consider Workholding Solutions:Proper workholding is essential for stable and accurate milling. HeroCnc provides a range of workholding solutions to ensure that the aluminum workpiece remains securely in place during the milling process.

- Regular Maintenance:To ensure consistent performance and longevity of CNC milling machines, adhere to regular maintenance schedules. HeroCnc provides guidelines for machine maintenance, contributing to uninterrupted production.

- Collaborate with Experts:HeroCnc prides itself on not just providing machines but also partnering with manufacturers to achieve optimal results. Collaborate with the brand’s experts to leverage their knowledge and experience in CNC milling aluminum.

Conclusion:

HeroCnc stands as a beacon of excellence in the world of CNC milling aluminum. The brand’s commitment to precision, high-speed capabilities, and versatility makes it a preferred choice for industries that demand nothing but the best. Whether you’re in aerospace, automotive, electronics, medical, or architecture, HeroCnc’s CNC milling solutions open up a world of possibilities. Unleash the power of precision with HeroCnc and experience the seamless fusion of technology and craftsmanship in aluminum machining.