The world of CNC machining is ever-evolving, and in 2024, titanium remains one of the most sought-after materials due to its exceptional properties. Whether you’re in aerospace, medical, automotive, or other high-performance industries, understanding the price dynamics of CNC machining titanium is crucial. This article delves into the costs associated with CNC machining titanium in 2024 and how partnering with a reliable manufacturer like Herocnc can optimize your production needs.

Understanding Titanium and Its Benefits

Why Titanium?

Titanium is renowned for its high strength-to-weight ratio, excellent corrosion resistance, and ability to withstand extreme temperatures. These attributes make it ideal for applications where durability and performance are paramount.

Applications of Titanium

- Aerospace: Components such as landing gear, wing structures, and engine parts.

- Medical: Surgical implants, dental implants, and orthopedic devices.

- Automotive: High-performance engine parts, exhaust systems, and suspension components.

- Industrial: Chemical processing equipment and power generation components.

Factors Influencing CNC Machining Titanium Price in 2024

Several factors contribute to the cost of CNC machining titanium. Understanding these can help you better estimate your project’s budget and find cost-effective solutions.

1. Material Costs

Titanium itself is an expensive material. The cost can vary based on the grade of titanium used. Common grades include Grade 2 (commercially pure titanium) and Grade 5 (Ti-6Al-4V), which is an alloy used for its superior strength and heat resistance.

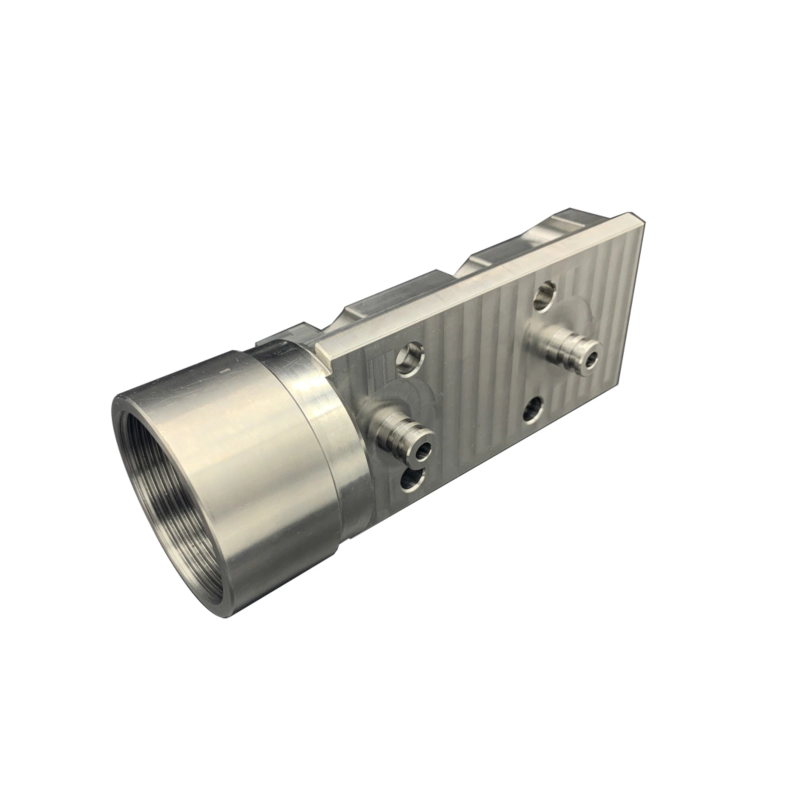

2. Machining Complexity

The complexity of the design directly impacts the machining time and, consequently, the cost. Intricate designs with tight tolerances and complex geometries require more time and advanced machinery to produce.

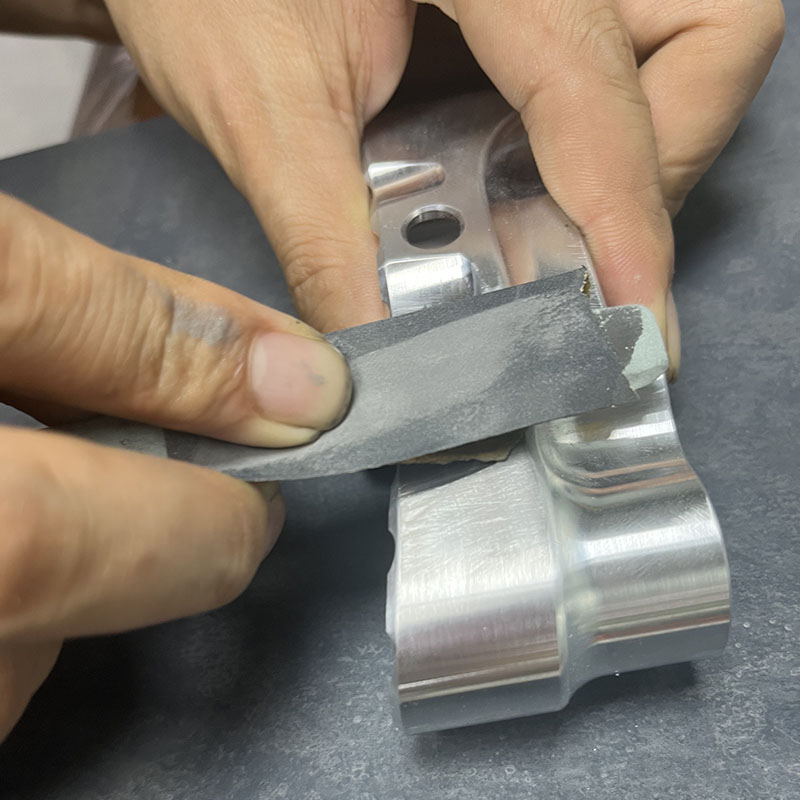

3. Tool Wear and Maintenance

Titanium is a tough material that can cause significant wear on cutting tools. This increases the cost of tooling and maintenance, which is factored into the overall machining price.

4. Labor Costs

The skill level of the machinists and the region where the machining takes place can affect labor costs. Skilled labor is essential for precision machining, especially for complex titanium parts.

5. Volume of Production

Higher production volumes can lead to cost savings due to economies of scale. However, for prototypes or low-volume production, the cost per part can be higher.

6. Post-Machining Processes

Additional processes such as heat treatment, surface finishing, and quality inspection add to the overall cost. These processes are crucial for ensuring the final product meets stringent quality standards.

Average Costs for CNC Machining Titanium in 2024

In 2024, the average cost for CNC machining titanium can range from $50 to $120 per hour, depending on the factors mentioned above. For simple parts, you might expect to pay around $50-$70 per hour, while more complex parts can push costs up to $100-$120 per hour or more.

Prototyping vs. Production Costs

For prototyping, costs can be higher due to the setup time and lower volume. Expect prices to be in the range of $1,000 to $5,000 for prototype parts, depending on complexity and material. For production runs, costs per part decrease significantly, potentially dropping to $100 to $500 per part for high volumes.

How Herocnc Can Help Optimize Your CNC Machining Titanium Projects

Partnering with an experienced and reliable manufacturer can make a significant difference in managing costs and ensuring quality. Herocnc stands out as a premier choice for CNC machining titanium, offering a range of services that cater to various project needs.

Comprehensive Manufacturing Solutions

Herocnc provides a full suite of manufacturing services, from effective prototyping to large-scale production parts. Their capabilities include CNC machining, metal casting, sheet metal fabrication, and parts finishing.

Expertise and Resource Integration

With rich manufacturing experience and the ability to integrate resources effectively, Herocnc can handle projects of any scale and complexity. Their expertise ensures that your parts meet the highest quality standards, reducing the risk of costly errors and rework.

Custom Rapid Manufacturing Services

Herocnc offers custom rapid manufacturing services, ensuring that your projects are completed on time and within budget. Their services are tailored to meet the unique requirements of each project, providing flexibility and efficiency.

Quality Assurance

Quality is paramount in CNC machining, especially when working with high-value materials like titanium. Herocnc employs rigorous quality control processes to ensure that every part meets exact specifications and industry standards.

Cost-Effective Solutions

By leveraging their extensive network and manufacturing expertise, Herocnc can offer competitive pricing for CNC machining titanium. Their ability to optimize production processes and reduce waste translates to cost savings for their clients.

Customer Support

Herocnc is committed to providing exceptional customer support, from initial consultation to post-production services. Their team of experts is available to discuss your project needs, provide free quotes, and offer guidance on the best manufacturing solutions.

Tips for Reducing CNC Machining Titanium Costs

While titanium machining can be expensive, there are strategies to minimize costs without compromising on quality.

1. Optimize Design for Manufacturability

Simplifying designs and reducing the complexity of parts can significantly lower machining time and costs. Collaborate with your manufacturer early in the design phase to identify potential cost-saving opportunities.

2. Choose the Right Grade of Titanium

Selecting the appropriate grade of titanium for your application can balance cost and performance. For example, using Grade 2 titanium for non-critical parts can be more cost-effective than Grade 5.

3. Leverage Economies of Scale

If possible, increase production volumes to take advantage of economies of scale. Larger production runs can spread setup costs over more parts, reducing the cost per unit.

4. Utilize Advanced Machining Techniques

Advanced machining techniques such as multi-axis machining and high-speed machining can improve efficiency and reduce tool wear, ultimately lowering costs.

5. Partner with a Reliable Manufacturer

Working with an experienced manufacturer like Herocnc ensures that your project is handled professionally, with a focus on quality and cost-effectiveness. Their expertise can help identify and implement cost-saving measures throughout the production process.

Final Toughts

CNC machining titanium in 2024 presents both challenges and opportunities. Understanding the factors that influence costs and partnering with a reliable manufacturer like Herocnc can make a significant difference in the success of your project. Herocnc’s comprehensive manufacturing solutions, expertise, and commitment to quality make them an ideal partner for all your CNC machining needs.

Whether you’re looking to produce prototypes or high-volume production parts, Herocnc offers the experience and resources to ensure your project meets the highest standards of quality and cost-efficiency. Contact Herocnc today for a free quote and to discuss how they can help you achieve your manufacturing goals.